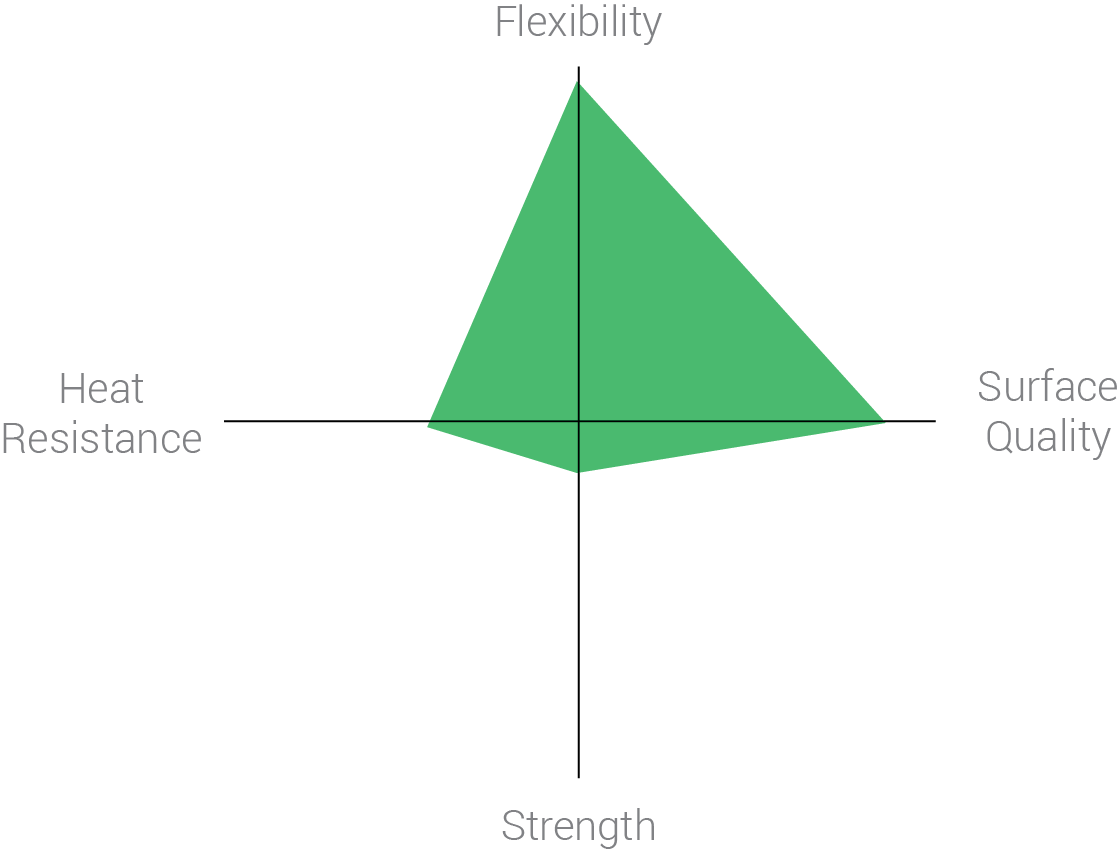

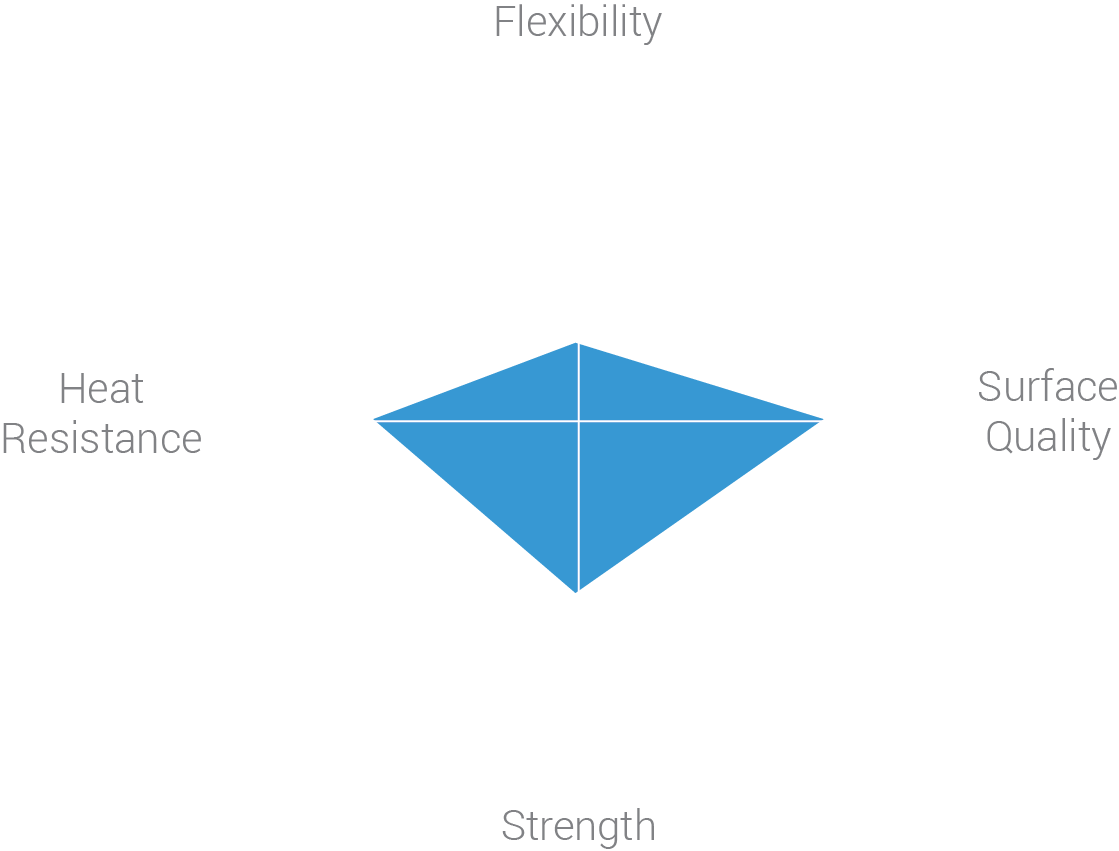

XForm PA22

Polyamide-based material used for functional parts.

XForm PA22 is ideal for a wide range of applications, from consumer goods to aerospace industry

Young’s modulus

1700MPa

Tensile strenght

50MPa

Elongation at break

15%

Our materials mechanical properties reflect injection molded plastics to deliver high

quality and durable results. Explore wide range of XForm materials; including rubberlike,

hybrid and composite, tough high-performance thermoplastics.

Polyamide-based material used for functional parts.

XForm PA22 is ideal for a wide range of applications, from consumer goods to aerospace industry

Young’s modulus

1700Tensile strenght

50Elongation at break

15

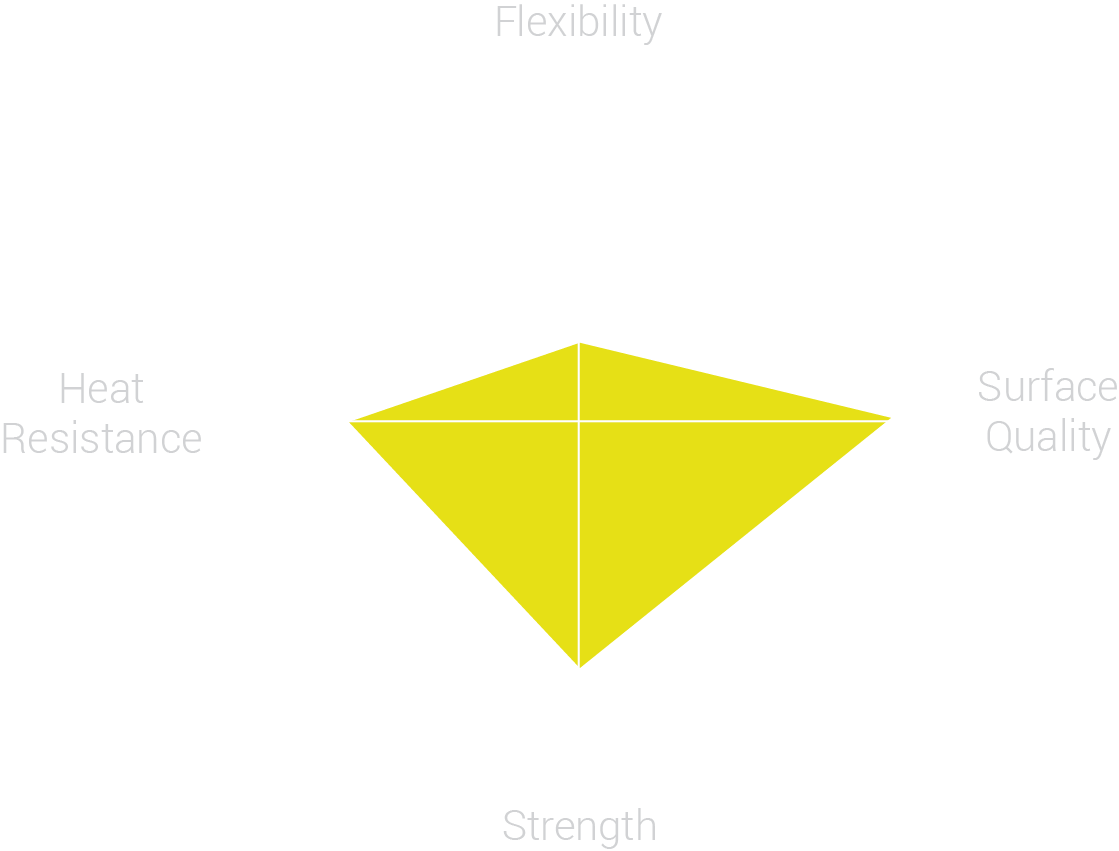

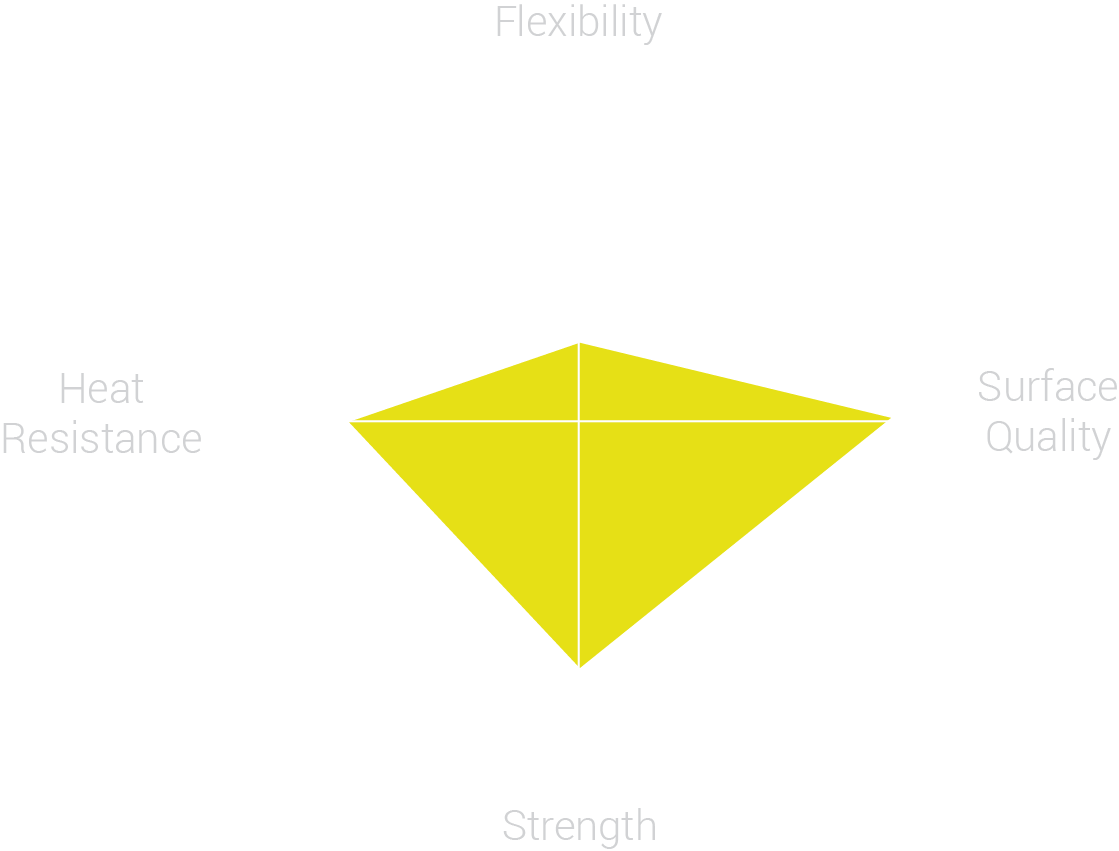

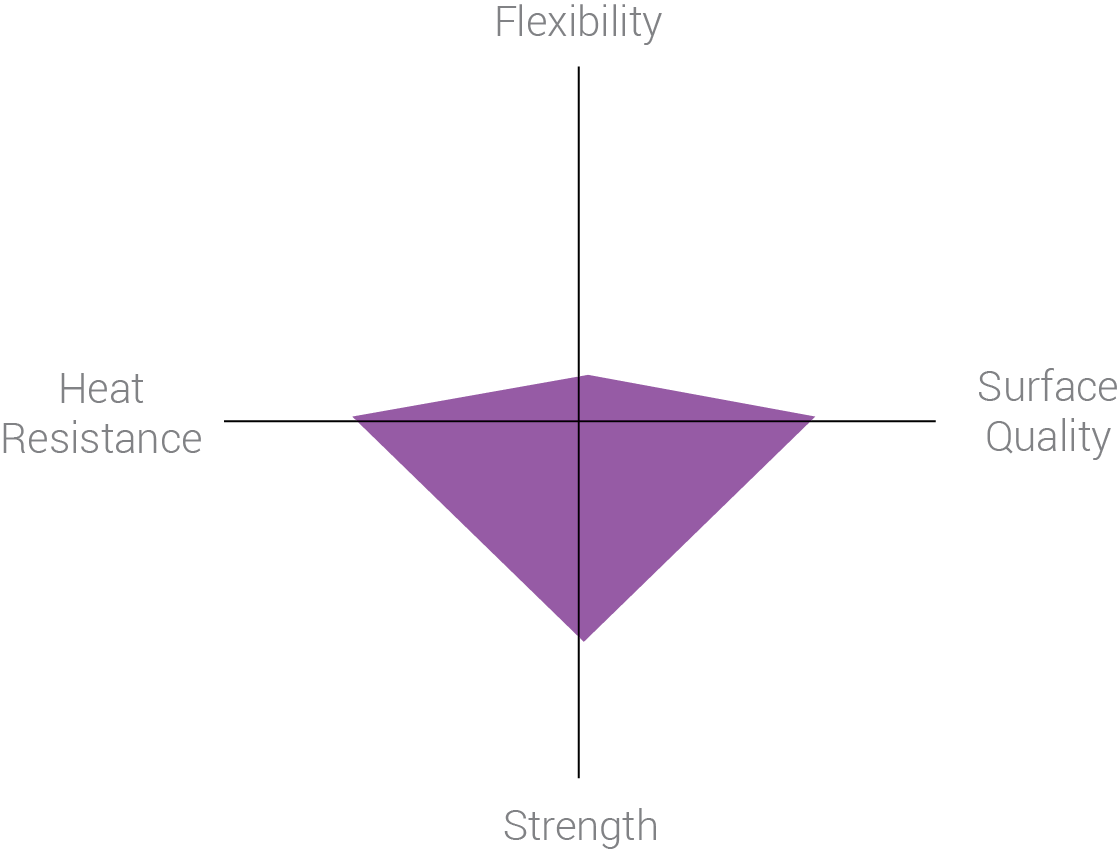

This material is defined as flexible and robust plastic. It has the highest surface quality. It can use for slightly more translucent parts.

Young’s modulus

1680Tensile strenght

47Elongation at break

35

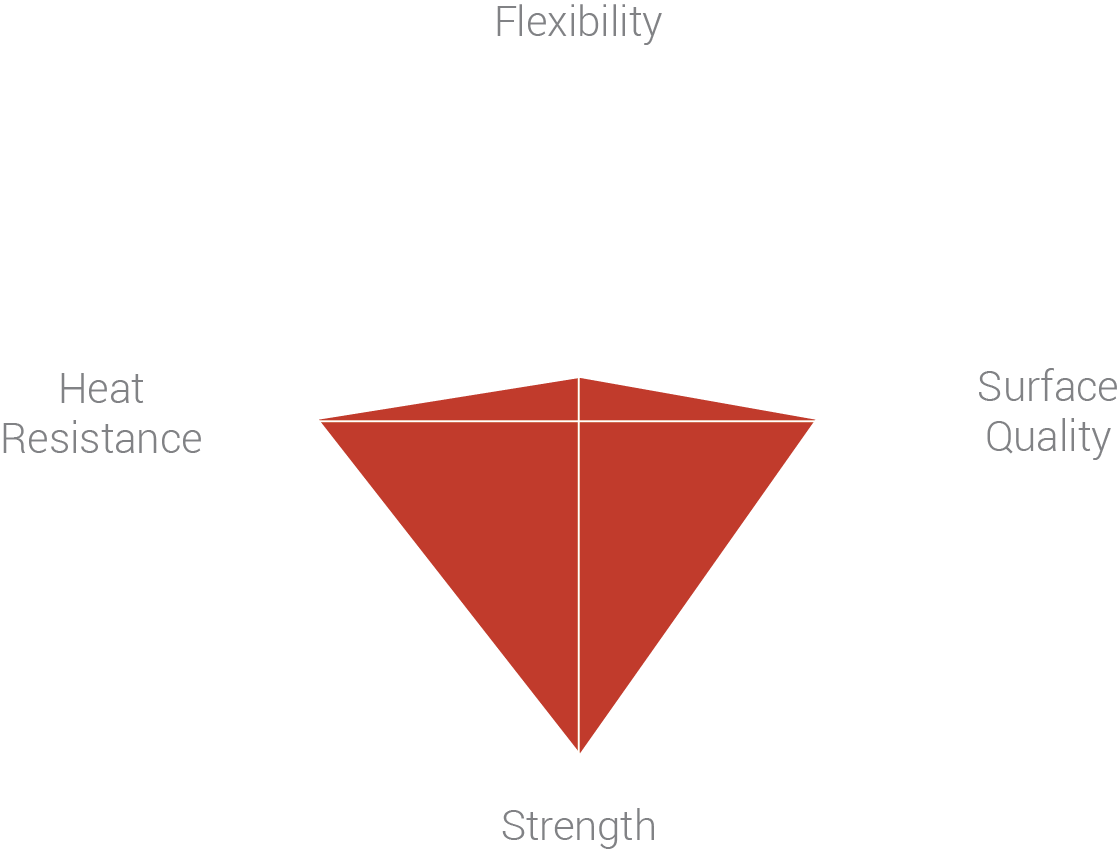

Glass powder reinforced thermoplastic used for wearproof functional parts. This material defined as strong durable plastic.

Young’s modulus

3000Tensile strenght

30Elongation at break

10

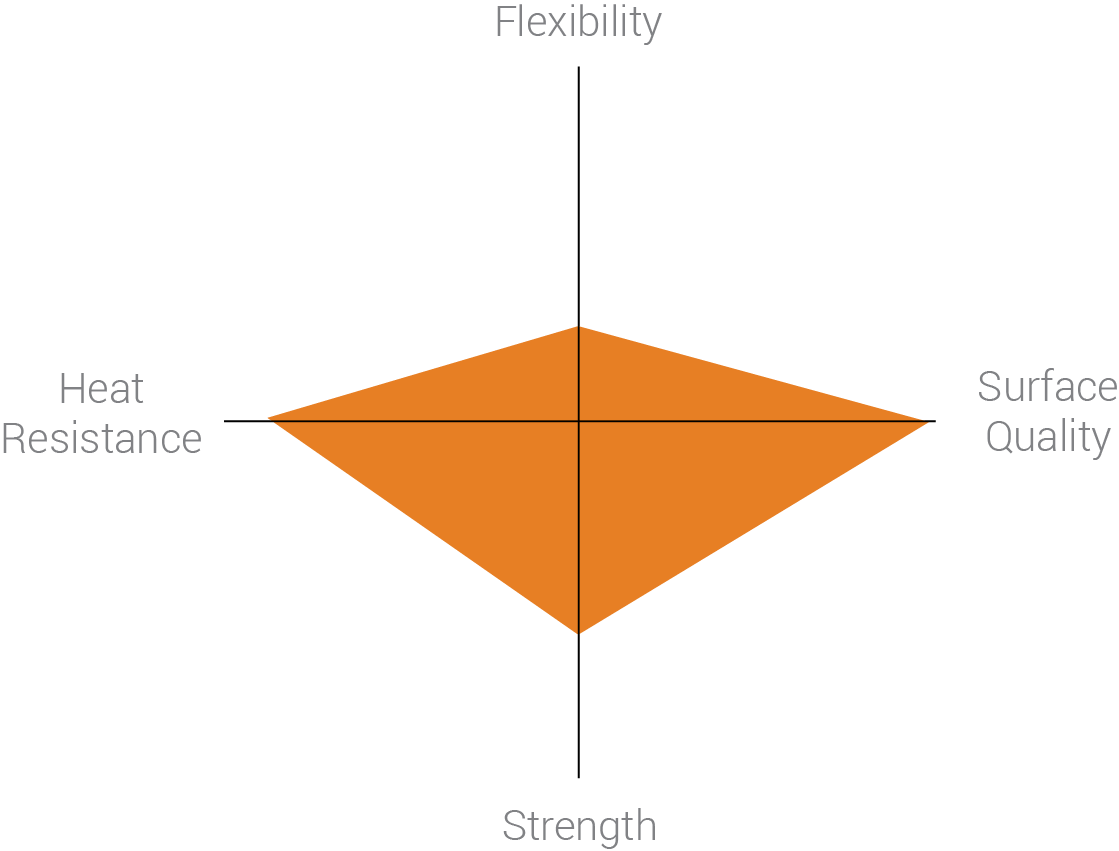

Aluminium powder reinforced thermoplastic used for functional parts. This material is defined as durable metal plastic. It has high strength and heat resistance.

Young’s modulus

4300Tensile strenght

50Elongation at break

5

Carbon-fiber powder reinforced thermoplastic used for functional parts. It defined as carbon-plastic. It has highest strenght and heat resistance.

Young’s modulus

8900Tensile strenght

82Elongation at break

3

Polyurethane - based thermoplastic is an elastomeric material for printing rubber-like parts and resistant to abrasion and stretching. A perfect fit for a wide range of applications such as hoses, grips, bellows, bumpers, seals, gaskets, tubes, athletic footwear and luxury items.

Young’s modulus

9Tensile strenght

10Elongation at break

300