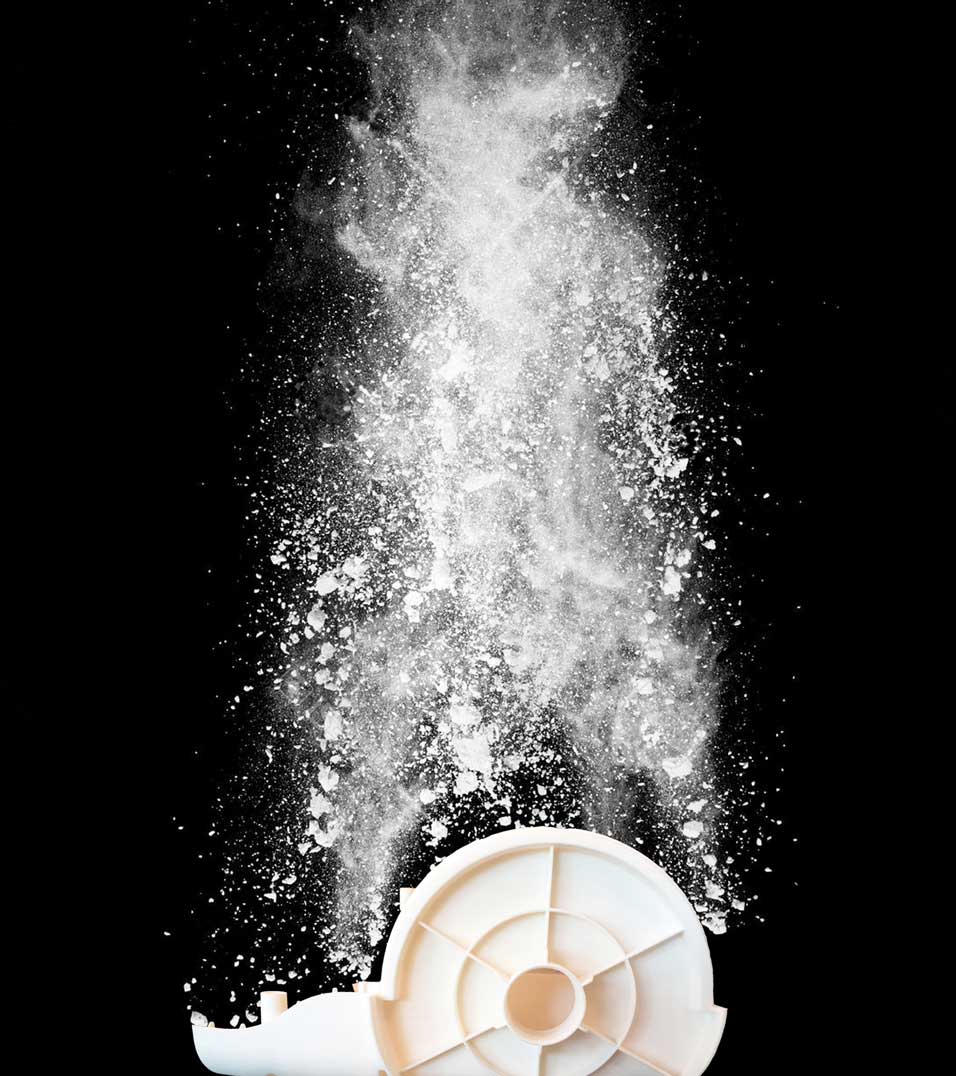

Layered Laser Fusion Technology

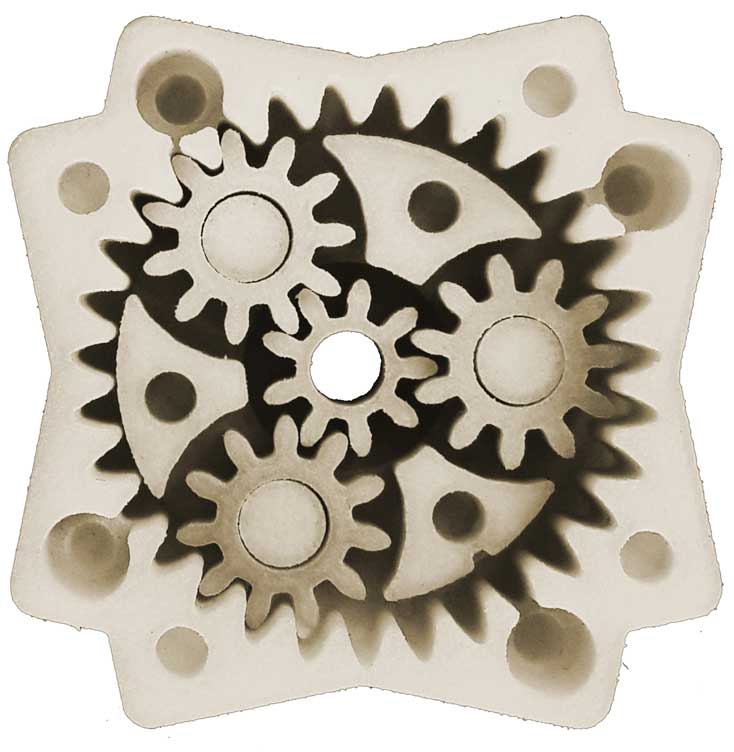

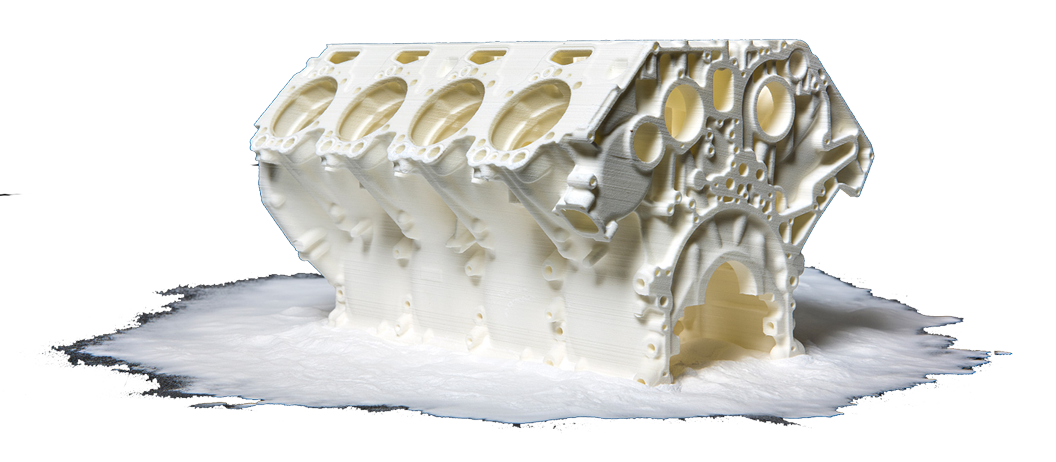

Layered Laser Fusion (LLF) is the rapid prototyping technology of choice for a range of functional prototype

applications, including those with snap fits, living hinges and other mechanical joints. The ability of SLS to produce

several pieces at one time also makes the process a good choice for Direct Digital Manufacturing of products

requiring strength and heat resistance.